EVs, the environment and climate crisis

Open all sections

Close all sections

– Climate crisis in general

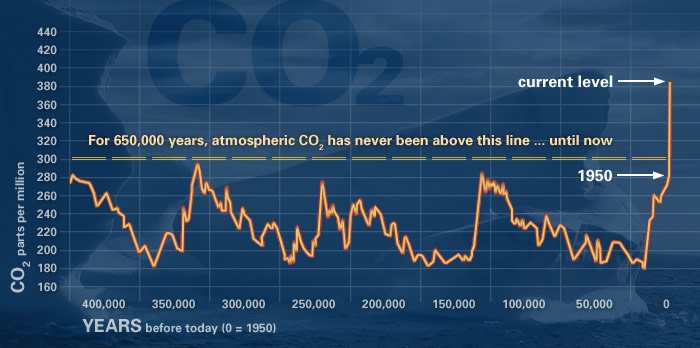

Humans add billions of tonnes of CO2 to the air every year by burning coal, oil and gas.

For 650,000 years the CO2 content in our air has never risen above 300 ppm

(300 C02 molecules per million air molecules), but that has changed in the past

few decades and it has now risen to over 410 ppm.

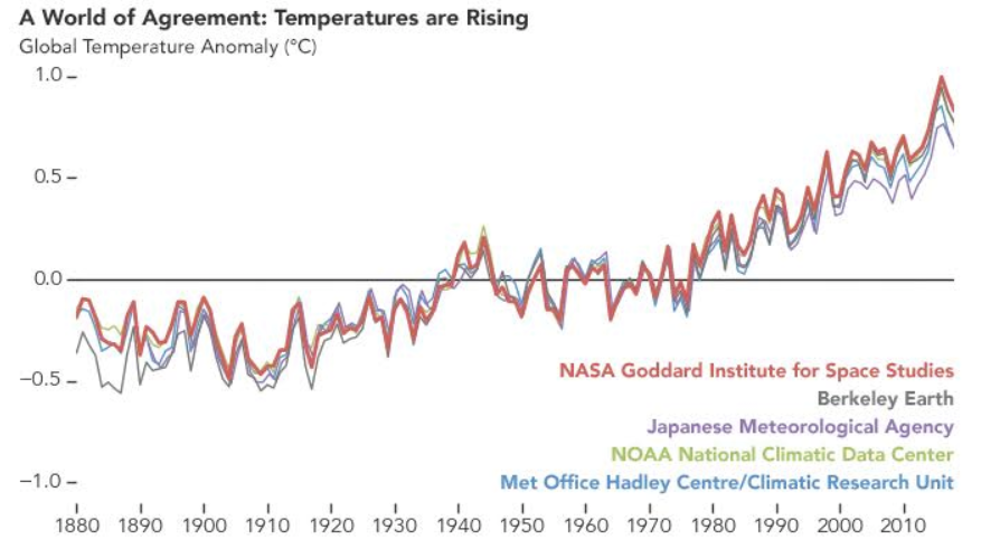

This has coincided with recorded increases in the global average temperature.

The extra heat from this warming means there is more energy in the atmosphere.

This makes extreme weather events more frequent and more intense.

The explainer below provided by The Guardian gives an excellent overview

of the problem and how EVs can contribute to the solution:

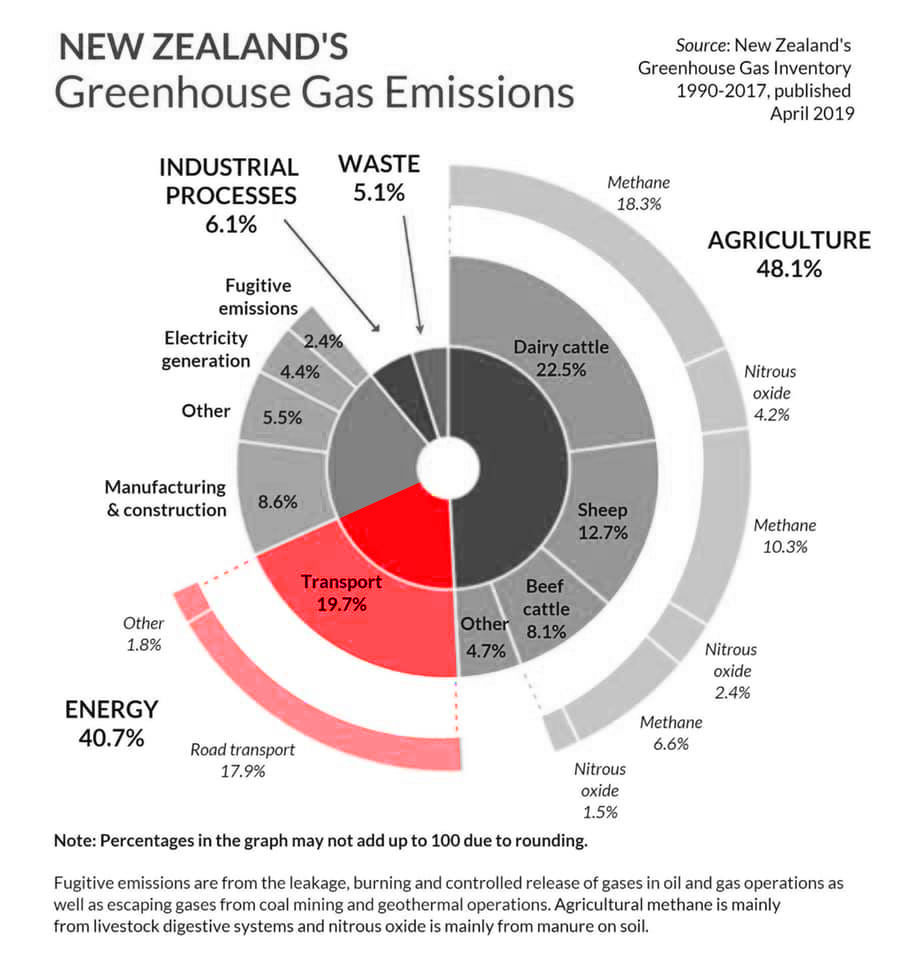

In New Zealand, 20% of our emissions come from transport. Using electric vehicles

would use reduce this by using renewable electricity sources instead of fossil fuels.

The cumulative, increasing emissions from vehicles are also having significant

effects on human health across the world.

Steps you can take

Transport

: If you can’t complete a journey by walking, biking, running

or public transport, then use an EV and see if your mates need a ride.

Research

: Inform yourself and make lifestyle changes. Everything from going

vegan to changing your lightbulbs helps.

– Should I be worried?

Yes.

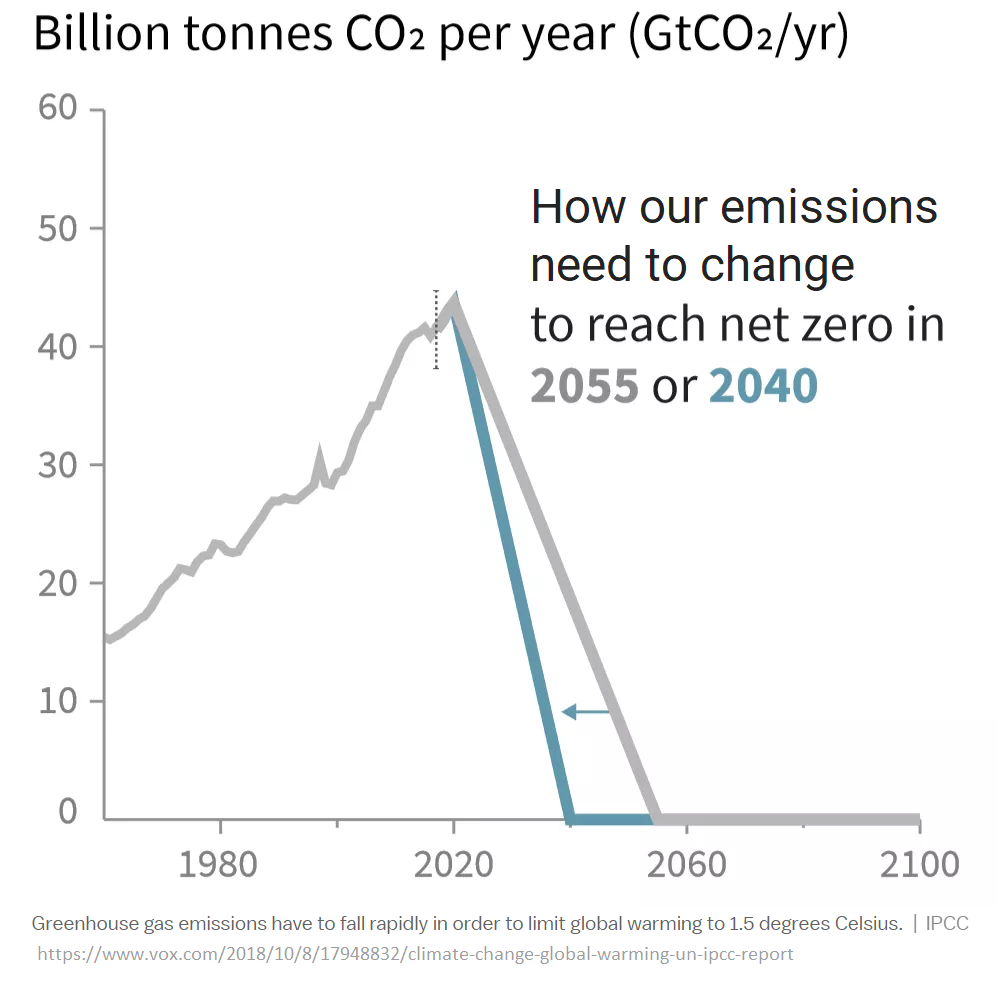

The United Nations’ Intergovernmental Panel on Climate Change (IPCC) provides

the world with an objective, scientific view of climate change.

The 2018 IPCC report projected that we (humans) have 12 years to make massive

and unprecedented changes to global energy infrastructure to limit global warming

to moderate levels.

Our way of life needs to change drastically in order to make the emission reductions

that this report says we need:

Climate change will lead to droughts and water shortages, more intense storms,

changes in agriculture, disruptions to the global economy and supply chains,

massive species extinctions, mass migration and climate refugees, frequent storms

and rising sea levels and flooding in many costal cities like Wellington and Auckland.

– Should I be angry?

Yes.

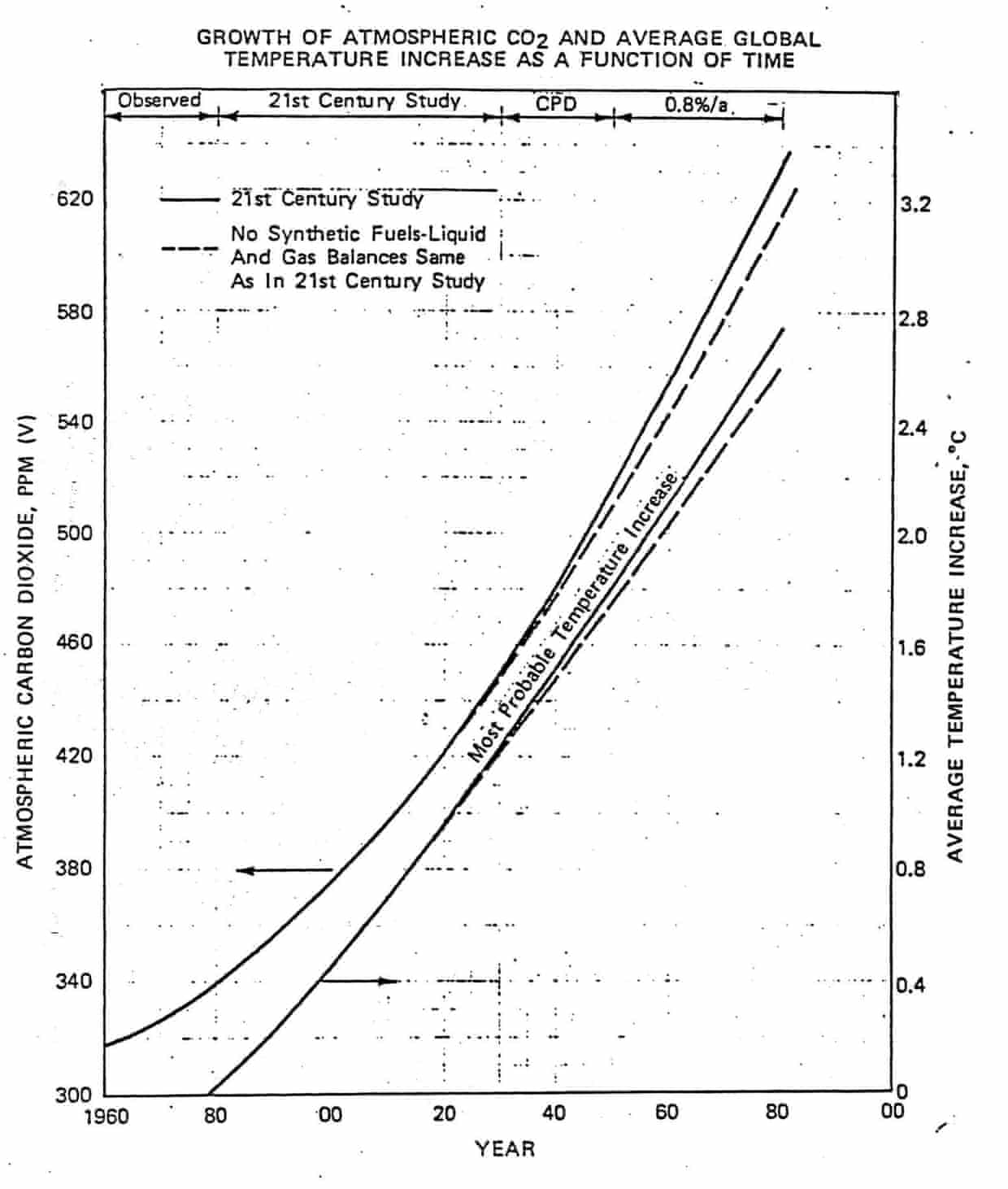

In the 1980s, oil companies assessed and forecast the planetary consequences of fossil fuel emissions.

In 1982 Exxon predicted that CO2 levels would reach around 560 parts per million by about 2060 and that

the Earth’s average temperature would rise by about 2°C:

Human effects on the climate were brought to the world’s attention in

1988

, when the director of NASA,

Dr James Hansen

was invited

to testify on the subject to the US Congress.

Despite this early knowledge, emissions have risen, misinformation has been spread

and environmental laws have been weakened or ignored.

– Manufacturing an EV

Driving an EV instead of a petrol car significantly reduces greenhouse gas

emissions without sacrificing convenience or mobility.

This is true both in the day-to-day driving, where you avoid burning petrol,

and over the lifetime of the vehicle.

Emissions released by manufacturing an EV are currently higher than those

released by manufacturing a gasoline-powered car, but this is small compared

to the emissions it avoids over its lifetime.

Below are a few of the many resources available online that discuss this topic

in detail:

International studies

show that manufacturing a mid-sized EV with an 150 km range

results in about 15% more emissions than manufacturing an equivalent gasoline vehicle.

For larger, longer-range EVs that travel more than 400 km per charge, the manufacturing

emissions can be as much as 68% higher.

However, the lifetime emissions are still, generally, lower than the equivalent

petrol car.

A NZ-based

lifecycle study commissioned by EECA

found a 60% reduction in CO2 emissions when comparing an EV to an ICE vehicle

in New Zealand.

– Resource depletion

A lifecycle study commissioned by EECA

shows that there is no significant impact on

resource depletion, such as the minerals used in battery and electric motor manufacture.

It also expects that improvements in battery technology and recycling

of the materials used in batteries and motors will further reduce resources used

in manufacturing EVs.

– Rare earth materials used in batteries

Most modern technology, including tech in fossil fuel vehicles and electric vehicles,

contains some amount of rare earth materials.

Rare earth materials are used to make powerful magnets that are used in some types

of electric motors and generators, and in everyday items like phone speakers and microphones.

Rare earth elements like neodymium, terbium, or dysprosium, are found

in a permanent magnet synchronous electric motors (PMSM). Not all EVs use

these motors, many EVs use induction motors which are based on copper coils

and do not require permanent magnets.

A lifecycle study commissioned by EECA

explains that, while some EV motors do contain

rare earth materials in small amounts, the resource depletion impact of rare

earth metals is not significant.

– Lithium

– Overview

Lithium is not categorised as either a rare-earth metal nor a precious metal.

The lithium that we can currently process is estimated to last 350 years,

while the crude oil we currently consume has been estimated to last for less

than 50 years by OPEC in 2018.

Most lithium is mined in Argentina, Chile, China and Australia but it can also

be produced from sea water as a by-product of desalination. However,

commercially viable methods of extraction have yet to be developed.

87% of known lithium is found in brine (salty water) deposits. This kind of lithium

is mined by pumping brine to the surface it is then extracted.

Previously lithium was seen as little more than a by-product made while

producing other minerals but this is changing as its value in batteries is realised.

– Environmental impact

If you got this far, then you’re either desperate for a reason to hate EVs,

or you’re arguing with someone who wants to hate them.

As with any type of mining, or industrial activity, there are some environmental

costs to extracting lithium from the Earth.

Two of the main arguments are (1) excessive water use and (2) impacts on local populations.

Lithium salts are extracted from water in mineral springs, brine pools, and brine

deposits. Like any other mining process, this requires water, which has been

steadily used up by other mining activities (e.g. copper) in lithium producing countries.

While this is a concern, other processes like fracking for natural gas are just as,

if not more water intensive:

Mismanagement of metal mines over the past decade has had some negative environmental impacts:

Humans make mistakes, and any endeavour that is not run properly will have

consequences. Take the

Deep Water Horizon oil spill

for example,

whose effects are still being felt today

.

It is important not to confuse the long term impact of driving an EV

with the general impact of mining, otherwise the only logical conclusion is

to abandon all technology altogether.

The impact of lithium mining is tiny when compared to the many oil spills

and ongoing environmental cost of extracting and burning fossil fuels.

However, this impact will lessen over time, as research into alternative methods

of energy storage is on going and EV battery recycling improves.

– Issues around labour and mining

Cobalt often makes up a small amount of a lithium-ion battery, used

in modern electronics like phones, laptops and EV batteries.

Cobalt is generally produced as a by-product during copper and nickel

mining around the cobalt belt which runs through

the Democratic Republic of Congo (DRC) in Africa, where 60% of cobalt

comes from. Labour conditions can be extremely poor and hard to track

in these subsistence living conditions and there are many reports

of child labour in

artisanal mines

.

EV battery manufacturers are also working to create cobalt-free batteries,

and the next generation of batteries are forecast to contain below

10% cobalt in the battery cathode.

The Cobalt Institute

,

whose members make up 70% of the cobalt production

in the world, has put into place a zero tolerance policy for child

or forced labour, and this is backed by its ability to trace cobalt

from rock to final product.

Continued pressure on automotive manufacturers is needed to ensure they only

source sustainable cobalt from the members who make up 70% of mined production.

Cobalt is not the only material or product with supply chain issues.

If you want to avoid products that have been made with forced or child labor,

this

2018 US Department of Labor guide

contains a list of products to consider avoiding.

For more information on EVs and cobalt, try these resources:

– Recycling batteries

A used EV battery still has value. It can be refurbished, repurposed or recycled.

An old EV battery can be removed and used to store electricity from solar PV panels

that would otherwise go to waste.

Most of the raw materials in an EV battery can be recycled.

Members of the Motor Industry Association of New Zealand (MIA) have committed

to a

code of practice

to have suitable systems in place for the use, capture,

return, refurbishment, reuse, recycling or disposal of EV and hybrid batteries,

with the aim that no batteries end up in landfills.

Even old EV batteries are infinitely recyclable and still too valuable to end up

in a landfill.

It is also much easier to safely dispose of an EV battery than it is

to safely dispose of the large cloud of greenhouse gasses and particulates

that are produced over the lifetime of a fossil fuel powered vehicle.

– Long tail pipe (emissions from electricity)

The “long tail pipe” of an EV refers to the emissions that come from generating

the electricity the EV uses.

In New Zealand, electricity is generated from about 80% renewables each year.

A good resource for understanding New Zealand’s energy emissions can be found

on

Ecotricity’s website

.

Even in a fully fossil fueled national grid, such as in parts of Australia

(where coal is often the primary energy source) EVs still emit fewer emissions

than a similar fossil fuel vehicle.

– Renewable electricity generation

New Zealand currently generates 43,000 Gigawatt-hours of electricity per year.

Over 80% of that comes from hydro, solar, wind and geothermal sources.

If every car in NZ was electric, they would require and additional 20%, or about

9,000 GWh of electricity generation. At present another 10,000 GWh of renewable

power has been consented, but is on hold until demand increases.

– Energy used in fossil fuel production

Energy is required to turn crude oil into petrol and diesel to power cars.

New oil fields now often need to operate in harsher environments and reach deeper

wells. This requires increasing amounts of energy and machinery to extract crude oil.

From there, crude oil is transported to refineries via pipeline, boat or train.

Heat and chemical treatments are needed to distil crude oil and produce gasoline.

Gasoline then needs to be transported through the supply chain before eventually

ending up in a tank underneath a petrol station.

– What about hydrogen?

– Making hydrogen fuel

Hydrogen is a gas that can be reacted with oxygen to create water and energy.

Hydrogen can be burned in a combustion engine, for example as rocket fuel,

or it can be used in a fuel cell to create electricity.

Hydrogen cannot be found on its own and harvested like oil. Instead, it needs

to be created, by breaking apart other substances, like coal, gas or water.

Most of the hydrogen made in NZ is made from natural gas using a process called

steam reformation. Hydrogen produced this way is called “blue” hydrogen because

it creates greenhouse gas emissions.

Hydrogen that is made from fossil fuels can only have low emissions

if

the emissions are captured and stored using

carbon capture and storage

techniques.

Carbon Capture and Storage (CCS) involves storing CO2, typically in in old,

used-up, underground oil and gas reservoirs, coal beds or saline formations.

This is not widely used and can cost around $150 US per tonne of CO2 stored.

CCS projects around the world only capture

0.8 million tonnes of CO2 annually

,

during that same amount of time, human activity creates

over 35 billion tonnes of CO2 gas

.

There is, however, also

research being done

on ways to store CO2 in materials

like concrete and carbon fibre. This would be much more cost-effective than burying it.

Hydrogen can also be made from water by using electricity to split water

into oxygen and hydrogen gas. This process is called

High Pressure Electrolysis

.

Hydrogen made this way is called “green” hydrogen if the electricity used

to make it comes from renewable energy sources.

Making hydrogen this way in New Zealand costs about $8.90 per kg before the costs

of transportation, storage and retail sale are added. In comparison, making it

from natural gas currently costs $2.70.

– Why make hydrogen?

Hydrogen fuel has a lot of practical uses. Making it could create more jobs

and allow countries like New Zealand and Australia to sell the renewable energy

they generate to other countries.

For more information about hydrogen fuel and refuelling stations,

the California Fuel Cell Partnership offers a

useful two-page overview

.

Concept Consulting has published an in-depth, detailed report on the potential future of hydrogen in New Zealand:

The Ministry for Business, Innovation and Employment has released a

report on the costs and impacts of transitioning to hydrogen for New Zealand

.

– Hydrogen powered vehicles

A hydrogen vehicle either burns hydrogen in a combustion engine, or uses it

to create electricity in an on-board fuel cell. That electricity is then used

to power an electric motor.

Benefits

Hydrogen cars can be refuelled faster, about the same time as refuelling a petrol car.

Modern hydrogen cars have a driving range the same as high-end EVs (about 600km) and

the exhaust they produce is water, not CO2.

An industry built around making, transporting and storing hydrogen could

potentially create more jobs.

Visiting hydrogen refuelling stations maintains the traditional fuel-supply business model.

Downsides

Hydrogen cars are expensive.

It is cheaper to make hydrogen from natural gas or coal than from water.

However, this process produces CO2, which is then released into the atmosphere.

There are currently no hydrogen refuelling stations in New Zealand and no

hydrogen vehicles for sale, as it costs up to $2M USD to build a hydrogen

refuelling station that won’t be used until enough hydrogen vehicles are on the road.

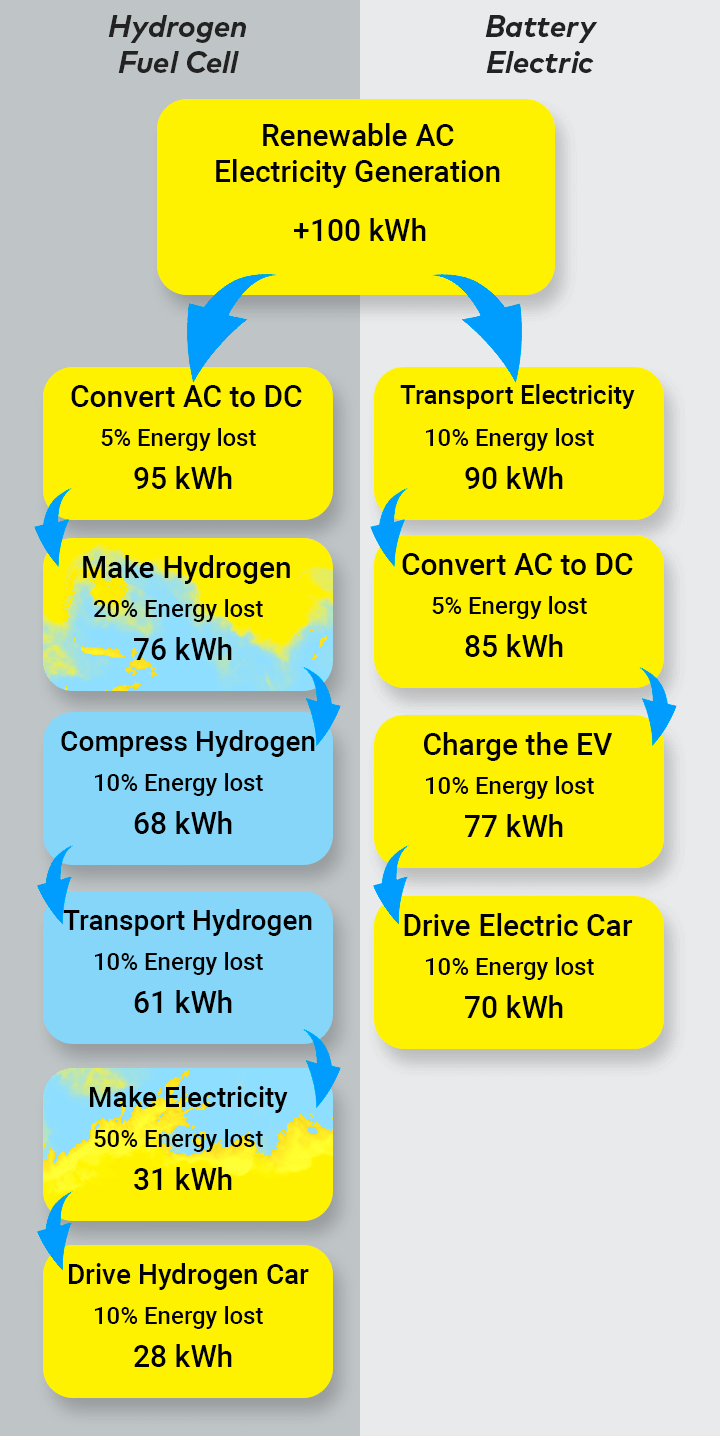

It takes about three times as much electricity to drive a car powered

by “green” hydrogen than it does to drive an EV.

This is because it takes electricity to make hydrogen from water,

some of that energy is then lost at each step before it is used

to turn the wheels of the car. The image below compares the efficiency

of hydrogen to the efficiency of an electric car:

Hydrogen gas

corrodes

many of the metals used to make pipes, which means

the existing gas and oil infrastructure would need to be upgraded

or replaced before it could carry hydrogen.

Below are some resources that you can use to learn more about the pros and cons

of both hydrogen and electric vehicles.

The Better NZ Trust provides resources that

compare the energy efficiency

of petrol, hydrogen and electric cars.

This

lengthy, somewhat challenging to read report

,

puts the cost of building 36 hydrogen fuelling stations in California at (

at least

) $3m USD each.

Each proposed station will supply between 200 and 1,200kg per day, depending

on its size. This is enough to fill up to 40 to 240 vehicles.

The energy efficiency percentage describes how much of the energy harvested

(digging up oil, making hydrogen or generating electricity) actually gets

turned into movement. The results are:

Battery EVs: 73% efficient

Hydrogen Fuel Cells: 22% efficient

Fossil Fuel Cars: 13% efficient.

A resource with numbers and analysis of the cost of operating hydrogen vs battery

vs petrol vehicles has been created by

Clean Technica

.

Hiringa

is a New Zealand based company

that makes hydrogen.

The Real Engineering Youtube channel has created an

informative video

about hydrogen powered vehicles.